What drove BMW to introduce Active Sound Design (ASD), i.e. speaker generated engine noise, in the F10 M5, of all cars ? How does it work and why does it even matter ?

Of my two years in Bucharest, Romania, I have one memory I particuliary remember, when I was aboard a friend’s E60 M5 (a first for me), at night, on a small road near the capital and going around enthusiastically. At that precise moment, my only distraction from the potential consequences of having so much power at your feet was the incredible concerto coming from the V10 5.0L engine under the hood. I had never fathomed that a car could sound this epic and that this could induce such feelings before, as my experience with cars was limited to 4-cylinder engines back then.

It was a fantastic car if only for its powertrain sound quality (PTSQ) and its engine was a great choice because of these characteristics:

Large displacement engine: With 5.0L the overall noise contribution from the engine will be rather high - Overall level generally increases with displacement.

Ten cylinders: High number of engine orders - See the previous post for all the benefits it adds to PTSQ.

Naturally aspirated: High contribution of intake & exhaust noise inside the cabin.

Obviously, whichever engine choice to replace a V10 would prove a challenge for any powertrain NVH engineer trying to maintain that level of PTSQ and the launch of the F10 M5 coincided with the conjunction of a few trends that would make this challenge even more daunting.

First of all, the regulatory aspect.

Exhaust gases Emissions: As emission standards worldwide are getting more stringent by the year, there is an incentive to go towards turbocharging as it offers lower emissions, as well as tipping the balance towards depollution considerations rather than NVH ones. Here for example is the evolution of the European emission standard:

Noise Emission: This regulation stipulates the maximum amount of exterior noise a car is allowed to generate under various levels of acceleration, also called the pass-by-noise. Its main contributors are engine/exhaust and tires and its general trend has always been towards reducing overall noise. This limit will depend on the country but the European standard is followed in a majority of countries: ECE R 51.03.

Then come the other considerations:

Performance: The choice of turbocharging from a strict performance point of view is obvious as it brings heaps of torque at very low engine speeds. It also drives the exhaust manifold geometry design, which has huge impacts on PTSQ that can be either negative or positive, depending on what you’re looking for.

Cabin NVH: As is the intent, the cabin of a 5-series has to be a quiet place to be in, regardless of speed. This also means that each iteration has to be more refined and quieter than its predecessor, using a stiffer BIW, better acoustic insulation from exterior noise (including the engine) and better vibration isolation (from both road and engine).

To summarize, here is what faced the powertrain NVH engineers at BMW when designing the F10 M5:

No more sweet V10

Lower displacement V8

Turbocharge all the things !

Lower permissible exhaust noise

Better insulated cabin

So, you have powertrain noise decreasing, less liberty on your exhaust design and less sound transmitted inside the cabin.

At this point, you have only a few options to reintroduce some engine noise at the driver’s ears:

Additional exhaust piping: One can go the way Mustang did it with the Boss 302 and simply adding a DIY way of increasing exhaust noise inside the cabin, but I’m not sure how European regulators would tolerate this trick. It also doesn’t help meeting your pass-by-noise target.

Exhaust valves: An exhaust valve (or tailpipe valve) is used to direct the pressure waves inside an exhaust. The valve is usually kept closed at low engine speeds to direct the waves inside heavily attenuating chambers, in order to meet pass-by-noise regulations and decrease undesirable noises inside the cabin. It fully opens at higher loads and/or rpms to minimize back-pressure and direct the waves towards a less restrictive chamber, increasing exhaust noise and PTSQ.

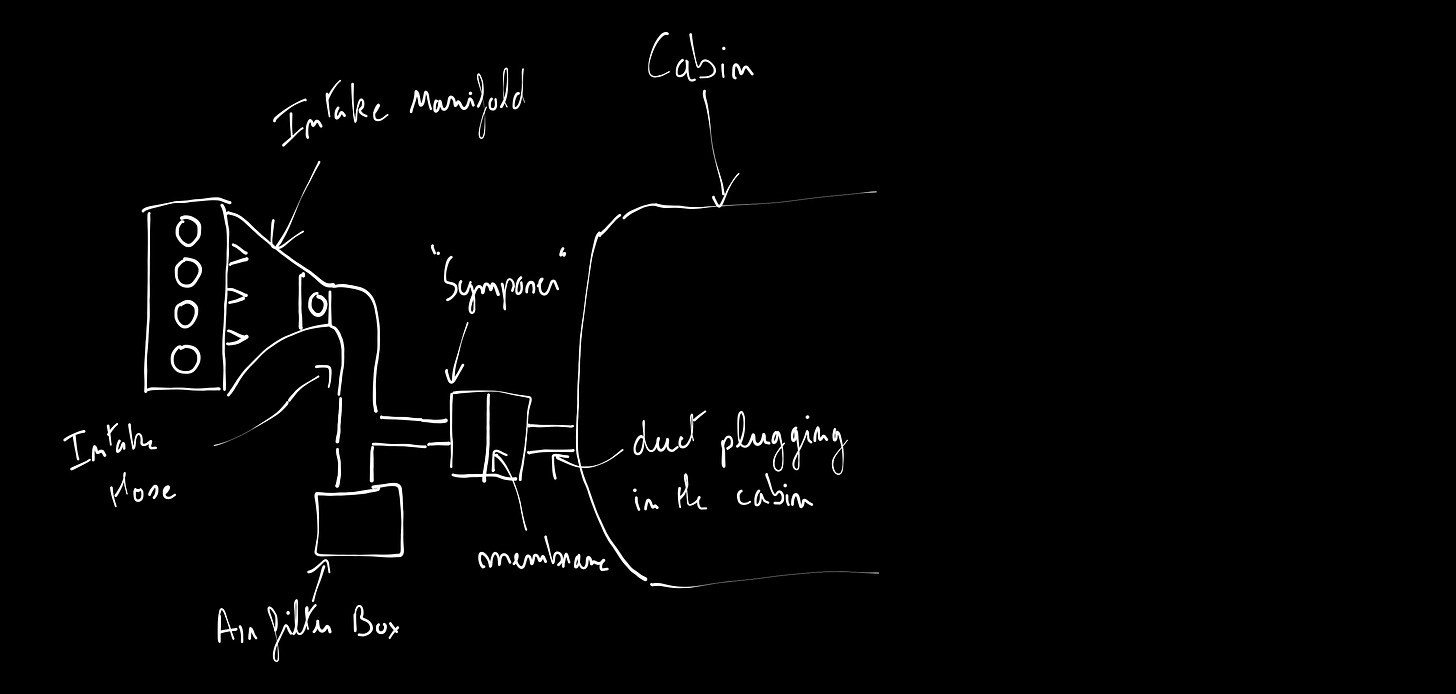

Engine air intake feed-pipe: sometimes called symposer, it is basically a pipe that branches on the air intake into the cabin. In the middle of this pipe, a little chamber containing a membrane allows only specific frequencies to be passed inside the cabin, while a valve controls how much noise is added:

This is considered to be a “natural” way (not by all) of enhancing PTSQ inside the cabin but is very limited in what it can achieve, it is usually limited to a narrow frequency band.

Finally, we have the Active Sound Design.

While BMW was one of the pioneers with the ASD, a lot of OEMS followed suit, such as VW with their soundaktor, Ford with their Active Noise Control and eventually Audi, Porsche, etc…

Here is how it basically operates:

A dedicated DSP reads the engine speed and throttle position (which corresponds to the load/torque request); based on the tuning maps designed by the NVH engineers, it sends the corresponding sound to be played to the amplifier which then mixes it with all the other audio sources and outputs it via the cabin speakers.

Is that a true engine sound that is replayed through the speakers?

Well, yes but not exactly. If you remember the post about the engine orders, you know that engine noise is basically a mix of different engine orders that varies with engine speed and load. As we’ve seen, engine orders are a fancy way to make a link between variations in frequencies and engine speed and in the end, the engine sound is just a bunch of sine-waves of different frequencies played at the same time (which is mostly true for every periodic signal, hence the Fourier transform) but neatly organized in engine orders for our convenience. Thus, if you have a sine-wave generator, you can recreate any engine noise, which is exactly what the DSP is doing.

The tuning maps look like this:

These are basically look-up tables: At every given moment, the DSP will look at what are the current engine speed and load, and will output the corresponding engine order sound level that the NVH engineer will have decided.

In this example, let’s look at what happens at 3000rpm at 50% load: The DSP will add a combination of 5+7=12 dB of order 1, a combination of 4+10=14 dB of order 1,5, etc... until 0+9=9 dB of order 12. Which is another way of saying, add 12dB of 50Hz, 14dB of 75Hz, …, 9 dB of 600Hz. Annnnd that is basically it.

The interesting part here though is, how do you come up with these maps ? I’ll keep the answer for another post where we’ll focus on general PTSQ design and good practices.

In the end, here is how it sounds like in the BMW F10 M5, with the ASD On and Off:

And here are the corresponding spectrograms:

Here we can immediately see which orders have been introduced with the ASD, as you just compare both spectrograms: 2.5th order, 4.5th order, 5.5th order, 7th order 9th order and probably a few higher ones that are harder to spot. As a bonus I circled what I believe is a gearbox whine happening in 3rd gear around 5000rpm.

As you can see, these are usually not order you would associate with a V8, especially 7th and 9th orders, although half orders are pretty common and are mostly useful to produce a nice, modulating growl at low engine speeds and a feeling of power at higher speeds. In my opinion, it is not the best sound design ever, as the 7th and 9th order are way too prominent and catch my attention every time.

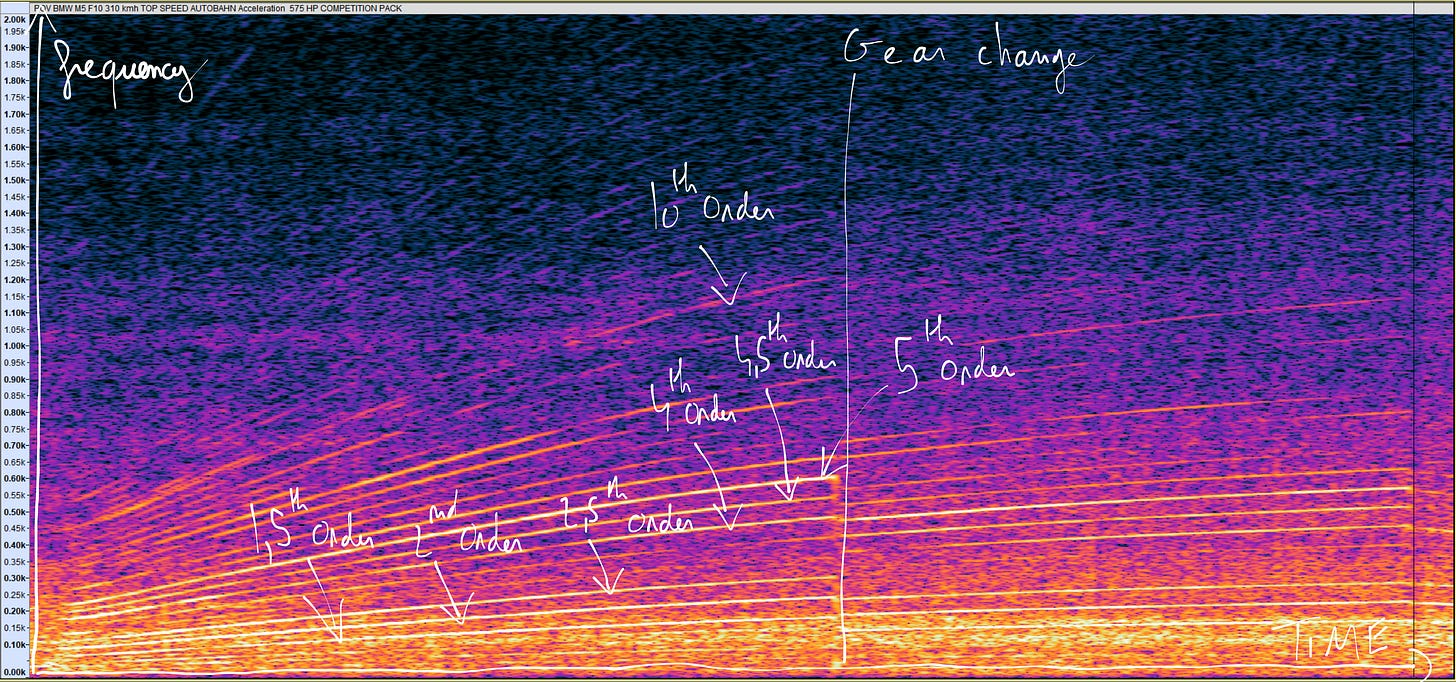

For reference, here is how the BMW M5 E60 V10 sounds like:

And the corresponding spectrogram:

As you can see, there is a loooooot more going on here, as every half-order is present in the cabin, up to engine order 15th or so.

What is also interesting, is that, although the M5 F10 competition introduced a few years later has the same-ish exhaust layout and engine, it sounds totally different (and better imo), thanks again to ASD:

And the usual corresponding spectrogram:

They got rid of 7th and 9th order, cranked up the lower orders and added some 5th and 10th orders, which are reminiscent of the E60 M5 V10.

The introduction of ASD in the BMW M5 F10, albeit not being the greatest example of it at the start, legitimized its use for all the other OEMs as most people never realized it was fake until being told so.

Nowadays, this technology has trickled down to pretty much every brand and segment, from the Lamborghini Urus to the honda accord and is often used in conjunction with other active technologies, such as exhaust speaker (in Audi) or with engine order cancellation which we’ll explore later.

I bet you drove a car with ASD and didn’t even notice.

It has gotten more complex too, as there can be as many maps as there are modes in the car (comfort, sport, sport+, etc..), it can be linked to the exhaust valve button (which sometimes won’t even affect the exhaust valve at all, I’m looking at you Porsche) and it can even simulate gear change farts as well as pops and bangs.

I hope that through this example you now have a better understanding of the ASD, why it was introduced and why it is much more than fake engine noise.

Part 3 is here: